Hydrogen, Copper, and PGMs: The Green Energy Transition

The global commitment to sustainable energy transition has never been stronger, now bolstered by international agreements like the Paris Agreement and the IEA Net Zero targets. Key to such a transition is a viable green fuel alternative to carbon-based solutions that can keep pace with humanity’s growing demand for energy and do so sustainably. Given the complexity and scale of such a goal, many potential solutions are in consideration. However, of the many, hydrogen is perhaps one of the most viable contenders. Used as a fuel source as long ago as 1842¹, the potential efficacy of hydrogen has long been understood but nonetheless has yet to be adopted for pervasive use due to cost concerns. However, with the current push toward green energy and recent advancements addressing cost and other technical concerns, interest in hydrogen has never been stronger.

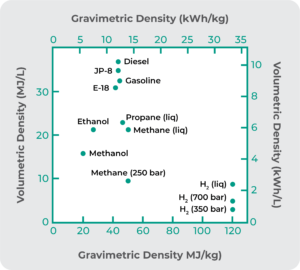

Central to hydrogen’s appeal is its abundance (the most abundant element in the universe²) and its ability to provide energy while generating green emissions under the right conditions. When isolated from specific sources such as water or ammonia, hydrogen releases only innocuous byproducts like water or nitrogen gas – i.e., zero carbon emissions1. Its potential becomes even more apparent when considering the energy, it packs – 140 MJ/kg, three times more than petroleum gasoline at 44 MJ/kg ³. Such characteristics naturally present a compelling alternative when compared to fossil fuels.

However, like any promising alternative, it’s not without its challenges. The processes of producing hydrogen are in and of themselves energy (and therefore cost) intensive. Hydrogen production from water –electrolysis – is accomplished by applying an electric current, splitting water into hydrogen and oxygen gas5. Similarly, production from ammonia – termed “cracking” – involves high heat to break down ammonia into its constituent nitrogen and hydrogen atoms6.

Yield in both cases is directly related to the efficient coupling of power to the chemicals being decomposed – and if carbon-based sources are used to provide said power, the sustainability aspect is lost to varying degrees of severity7. Green hydrogen uses only sustainable energies (wind, solar, etc.) to generate the power necessary to electrolyze water and generate hydrogen for fuel. As this results in the generation of no carbon emissions, it is thus the only truly net zero hydrogen fuel pathway.

While green hydrogen is of primary interest in this work, several more variants are important to consider for context – and demonstrate how variable the sustainability of hydrogen is with processing. Gray hydrogen is the most common in industry today and uses what is called steam reforming, which brings methane (CH4) gas together with steam, the heat and pressure of which separate the methane and generate hydrogen gas, but also carbon monoxide (CO) – and so is a direct contributor to greenhouse gas emissions. Blue hydrogen is identical to gray in the initial process (using steam reforming), but then implements some post-carbon capture technology to prevent the emission of carbon-based products into the atmosphere. A last consideration of note is pink hydrogen (sometimes called red or purple), which is electrolysis driven by nuclear energy8.

Water Electrolysis:

2 H2O (l) + 2e– → H2 (g) + 2 OH– (aq.),

in solution w/ current applied

Ammonia Cracking:

2NH3 (L) → N2 + 3H2, w/ heat and a catalyst

Steam Reforming:

CH4 (g) + H2O (g) → 2H2 + CO, w/ heat and pressure

Even, and in some cases especially, when limiting consideration only to net zero (green hydrogen) methods, the biggest hurdle opposing the widespread adoption of hydrogen as a fuel is cost4. This cost is primarily due to the materials used in production, the quality of which has a critical role in performance and efficiency. In the case of electrolysis, and on a related note, hydrogen fuel cells utilize precious (i.e., expensive) metals – copper and platinum group metals (PGMs).

Figure 1. The energy density of various fuel sources in terms of volume and mass3.

Green Energy Transition is a Metals Transition

With the history, aspects, and challenges of hydrogen as fuel now laid out, the outline of a potential pathway to energy transition begins to take shape with green hydrogen at the center. The critical enabler would be the improved availability and cost reduction of PGM and copper – the crucial metals that facilitate the superior performance of hydrogen production and fuel cell operation in their use as reaction catalysts and chemical stabilizers9, 10. In short, the problem of energy transition is a problem of transition metals.

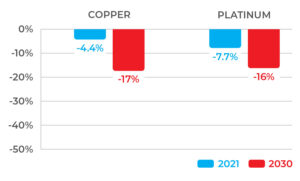

Unfortunately, precious is an apt description as mining these materials is sparse and unevenly distributed throughout the globe. As such, these materials are particularly susceptible to unstable supply chain demands and geopolitical concerns and have difficulty responding to the recent spike in demand that’s been brought about by recent innovations in sustainable energy solutions like hydrogen production. Both copper and PGMs are already entrenched in a supply deficit, a situation poised to only intensify to an approximately 17% deficit by 2030, deteriorating by about 2% per year11. This is a looming logistic issue that represents a fundamental obstacle to the industry, especially as hydrogen and other cleantech solutions continue to evolve. Further complicating the scenario, simply increasing production or refining is not as straightforward as it may seem. Mining processes are rife with risks and entail substantial environmental impact. The requirements for heavy capital infrastructure and equipment incur a significant carbon cost, contributing to environmental degradation.

Figure 2. Market deficit for copper and platinum metals in 2021 and projected to 203012.

With these considerations in mind, in order to facilitate a genuine transition to green hydrogen as a sustainable energy source, it is imperative to address these deficits in the precious metal supply. Any remediation must occur in a manner that not only curtails costs but also mitigates the production demands and the associated sustainability concerns. A viable pathway for hydrogen fuel as an energy transition can be developed only by addressing both aspects.

Recycling as a Key Link in the Energy Transition Pathway

Fortunately, there is already a reservoir of precious metals available and up for the challenge —the material discarded as impure waste during production, or the materials left in products after their first life use. In 2019, over 50 million metric tonnes of electronic waste were produced, with only about 20% being formally recycled13. This discarded material represents a colossal loss in value, amounting to nearly $50 billion, $2.5 billion of which are PGM materials alone. More than 43 million tons of copper are wasted in the original mining process and is considered too inconvenient to extract for mainstream production. The true pathway to energy transition is a comprehensive, industry-wide shift to a circular economy model in which the recycling of essential metals in clean technology solutions is repurposed, addressing supply deficits, maintaining net zero impact, and recovering billions in resources otherwise lost to waste.

This is where the team at pH7 is aspiring to make a difference. We’ve made it our mission to create sustainable, efficient solutions to the extraction of critical precious metals to support hydrogen energy transition. For copper, our technologies enable the extraction of copper from common mining waste materials like chalcopyrite – which contains traces of copper. For PGM, we’ve developed 100% green solvents for metal isolation and extraction – extraction with no waste, low energy consumption, selective isolation, and near zero environmental impact. Through extraction, we can improve recycling; through recycling, we can supplement the deficit of critical metals; and through supply, we can help drive down hydrogen cost and, perhaps in some small way, help the world get one step closer to a green energy transition fueled by green hydrogen.

References:

1 Hydrogen: Enabling a Zero Emission Society. Energy central. (2022). Retrieved from https://energycentral.com/system/files/ece/nodes/579157/

2 Hydrogen explained. (2022, January 20). Retrieved from https://www.eia.gov/energyexplained/hydrogen/

3 Hydrogen storage. (n.d.). Retrieved from https://www.energy.gov/eere/fuelcells/hydrogen-storage

4 Alternative fuels data center: Hydrogen benefits and considerations. (n.d.). Retrieved from https://afdc.energy.gov/fuels/hydrogen_benefits.html

5 Hydrogen production through electrolysis. BulletinH2. (n.d.). Retrieved from https://www.h2bulletin.com/knowledge/hydrogen-production-through-electrolysis/

6 Potential Roles of Ammonia in a Hydrogen Economy. US Dept of Energy. (2006 Feb). Retrieved from: https://www.energy.gov/eere/fuelcells/articles/potential-roles-ammonia-hydrogen-economy

7 Hydrogen basics – Production. (n.d.). Retrieved from https://www.fsec.ucf.edu/en/consumer/hydrogen/basics/production.htm

8 The hydrogen colour spectrum| National grid group. (n.d.). Retrieved from https://www.nationalgrid.com/stories/energy-explained/hydrogen-colour-spectrum

9 Copper could help unlock the clean-energy potential of hydrogen fuel cells. (2019, November 1). Retrieved from https://hub.jhu.edu/2019/11/01/hydrogen-fuel-cell-copper-catalysts/

10 The growing importance of platinum in the hydrogen economy. BulletinH2. (n.d.). Retrieved from https://www.h2bulletin.com/platinum-hydrogen-economy-wpic/

11 Platinum Group Metal Catalysts: Supply Chain Deep Dive Assessment. US Dept of Energy. (2022, Feb 24). Retrieved from: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.energy.gov/sites/default/files/2022-02/PGM%20catalyst%20supply%20chain%20report%20-%20final%20draft%202.25.22.pdf

12 Lux research. (n.d.). Retrieved from https://members.luxresearchinc.com/

13 Enough with the E-waste”. ESG Investor. (2023, July 26th ). Retrieved from https://www.esginvestor.net/enough-with-the-e-waste/